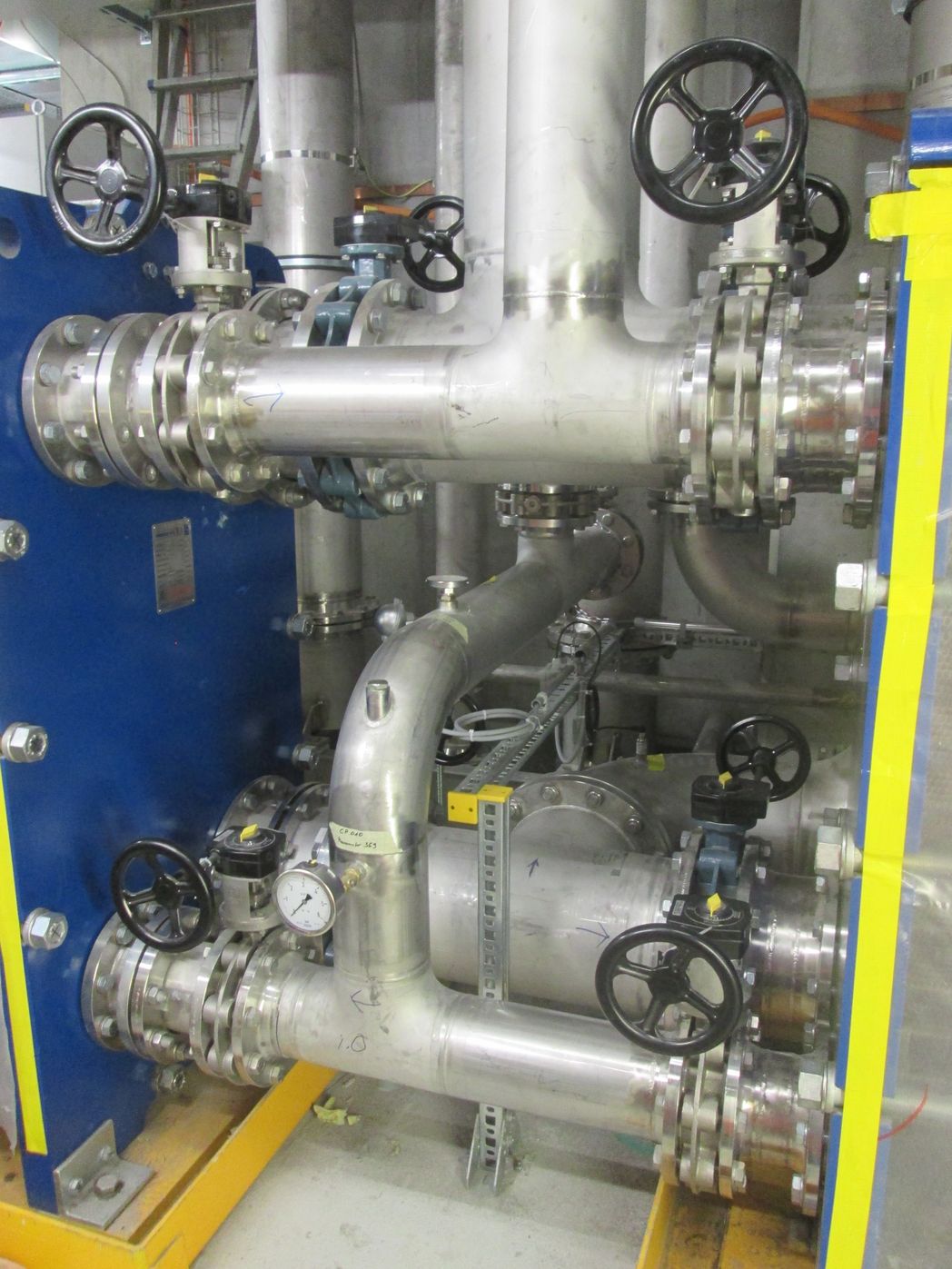

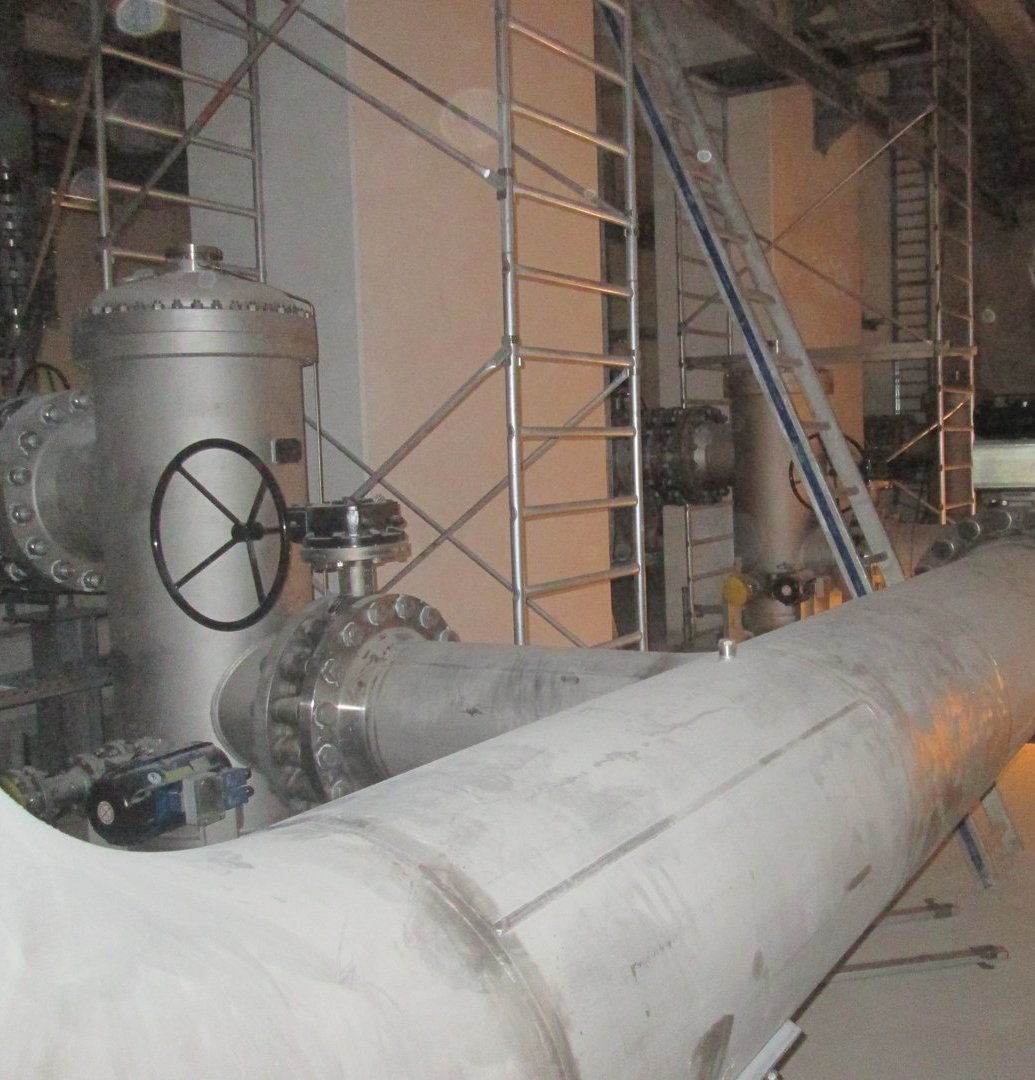

Linthal 2015 project; Linth-Limmern pumped storage plant Pipelines for cooling water system

Project description:

Engineering, design, prefabrication and assembly of a total of over 2000 metres of pipelines for the primary and secondary cooling circuits of the cooling water system.

Technical data:

Diameters and wall thicknesses of the pipelines designed and specified in accordance with EN 13480-3 and EN 10217-7. For the design of the primary cooling circuit, a maximum operating pressure of 40 bar (PN 40) at a water temperature of 20 °C and a welding factor of 0.85 were taken into account.

For the design of the secondary cooling circuit, a maximum operating pressure of 10 bar (PN 10) at 20 °C and a welding factor of 0.85 were taken into account.

- All pipelines were made from 1.4404 material and delivered.

- Pipe dimensions from DN 65 to DN 600

- Wall thicknesses from 2 to 12 mm

- Assembly took place at the power station located inside a cavern at an altitude of approx. 1700 metres above sea level.

- Non-destructive tests (VT, PT, UT, RT and pressure tests) were conducted at the Sennwald plant and on-site.

German

German